-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

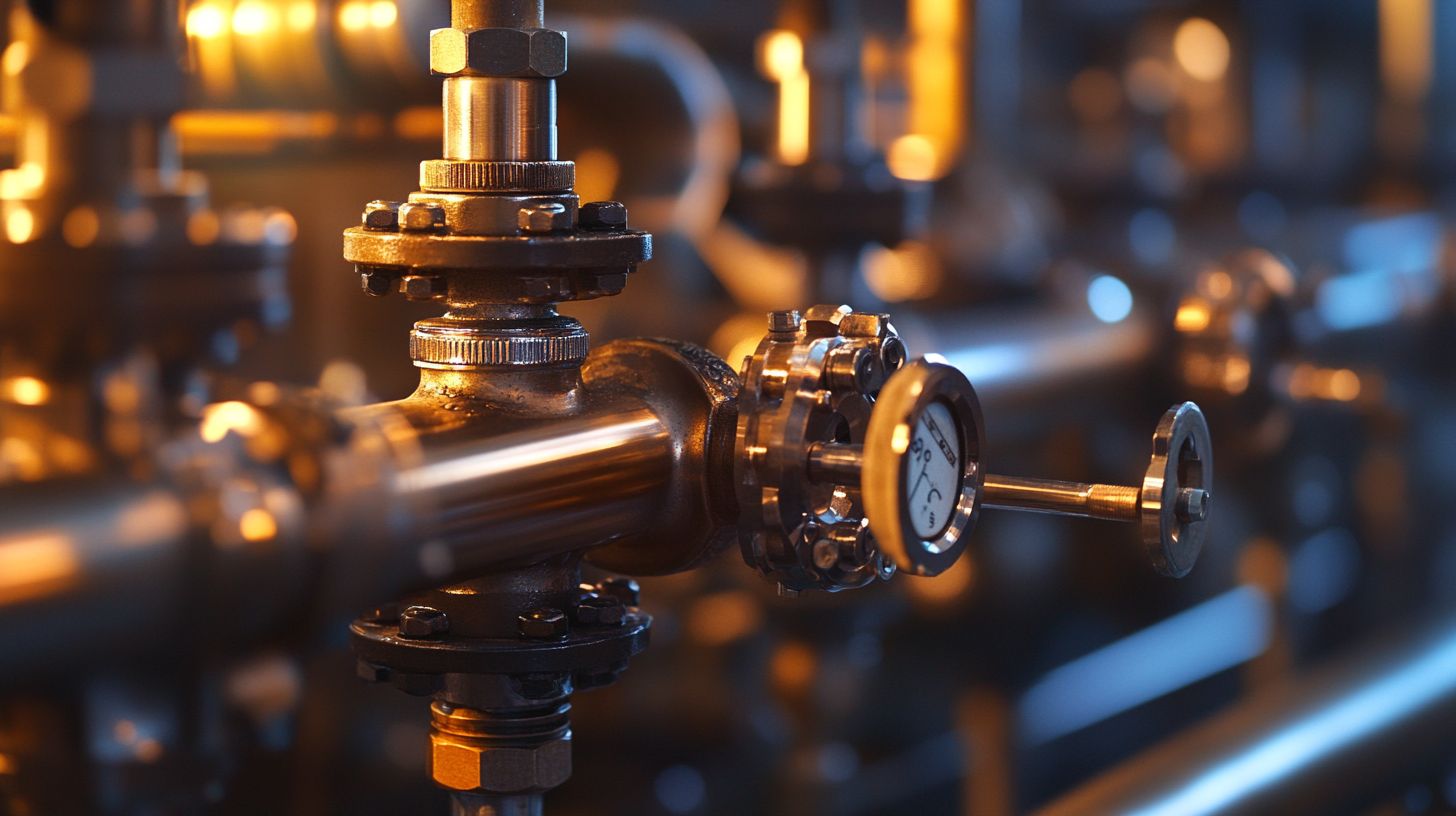

Exploring the Unique Features and Applications of the Best Pressure Valves for Global Buyers

In today's industrial landscape, the importance of pressure valves cannot be overstated, as these essential components play a critical role in maintaining safety and efficiency across various applications. This blog delves into the unique features and diverse functionalities of the best pressure valves available to global buyers, providing insights into how these products can enhance operational performance. From regulating fluid flow to ensuring system integrity, pressure valves are indispensable in sectors ranging from manufacturing to oil and gas. As we explore different types of pressure valves, readers will gain a nuanced understanding of their applications and the factors to consider when selecting the most appropriate options for their needs. Whether you're an engineer seeking technical specifications or a business leader aiming to optimize your processes, this guide will serve as a valuable resource in navigating the world of pressure valves.

Understanding Pressure Valves: Key Performance Metrics and Standards in the Industry

Pressure valves play a crucial role in maintaining safety and efficiency across various industries. Understanding the key performance metrics, such as response time, stability, and accuracy, is essential for selecting the right valve for specific applications. As highlighted at the recent Subsea Tieback Forum, advancements in technology are paving the way for pneumatic control valves, which offer ultra-low overshoot and rapid response times. This is particularly significant for industrial processes that require precise control.

When evaluating pressure valves, consider the following tips: First, look for valves that not only meet industry standards but also incorporate innovative designs to enhance operational performance. For instance, recent developments in cartridge assembly designs have led to improved sealing and leak-tight performance in pressure relief valves. Second, keep an eye on market trends and forecasts; the global industrial valve market is expected to grow significantly, indicating increasing demand and the importance of investing in reliable pressure valve solutions.

Lastly, prioritize safety by choosing valves that adhere to established safety protocols and regulations within the sector. The Responsible Care initiative underscores the commitment to safe chemical operations, highlighting the role of high-integrity pressure protection systems in mitigating risks in industrial environments. By focusing on these key performance metrics and standards, global buyers can make informed decisions that enhance both safety and operational efficiency.

Comparative Analysis: Top Pressure Valve Types and Their Ideal Applications

When selecting the best pressure valves, understanding the different types available is crucial for optimal application. Among the most popular types are globe valves, gate valves, and safety relief valves. Globe valves are ideal for throttling flow and can easily manage varying pressure levels, making them suitable for applications in water systems and chemical processing. On the other hand, gate valves are primarily used for fully opening or closing the flow, making them perfect for high-pressure systems where minimal flow resistance is needed.

Tips: When choosing a pressure valve, consider the material compatibility with your fluid and the required pressure rating. This ensures reliability and safety in your application.

Safety relief valves play a vital role in protecting pipeline systems from overpressure by automatically releasing excess fluid. They are commonly used in oil and gas, as well as steam application scenarios. Utilizing the right pressure valve type can enhance system efficiency and reduce the risk of potential hazards.

Tips: Regular maintenance and inspection of your pressure valves can prevent unexpected failures and prolong their lifespan. Always follow manufacturer guidelines for servicing.

Global Market Insights: Current Trends and Projections for Pressure Valve Demand

The global market for pressure valves is witnessing significant shifts, driven by various trends and technological advancements. According to recent reports, the demand for electronic expansion valves is projected to grow substantially from USD 886.5 million in 2025 to USD 1.986 billion by 2035, reflecting a compound annual growth rate (CAGR) of 8.4%. This surge is largely attributed to the increasing adoption of smart technologies in industrial applications, where intelligent and IoT-integrated valves are becoming essential for efficient and automated processes.

Similarly, the HVAC valve market is expanding rapidly, with the current phase of digital transformation encouraging the development of sophisticated valve systems equipped with sensors for monitoring and control. This shift is expected to enhance system efficiencies and energy savings, aligning with broader industrial automation trends driven by regulatory requirements. As global industries invest in safety and reliability, demand for backflow preventers is projected to exceed USD 614.6 million by 2035, growing at a CAGR of 3.8%, underscoring the increasing necessity for plumbing safety and clean water solutions.

These insights into the pressure valve market indicate robust growth projections across various segments, reflecting a dynamic landscape that is continually evolving in response to technological innovations and market needs.

Global Pressure Valve Market Demand (2023 Projections)

Material Selection in Pressure Valve Manufacturing: Impact on Performance and Longevity

In the realm of pressure valve manufacturing, material selection plays a pivotal role in determining both performance and longevity. The choice of materials not only affects the pressure handling capabilities of the valves but also their resistance to corrosion and wear. Industry reports indicate that approximately 30% of valve failures can be traced back to inadequate material choice, highlighting the critical nature of this decision for manufacturers. For instance, stainless steel valves, known for their excellent strength and resistance to corrosive environments, are widely favored in industries such as oil and gas, where durability is paramount.

Furthermore, advancements in material technology have introduced high-performance alloys and composite materials that enhance the operational efficiency of pressure valves. According to a recent market analysis by the Global Valve Manufacturing Association, the demand for innovative materials in valve production is projected to grow by over 15% annually, driven by the need for improved energy efficiency and environmental sustainability. These advancements not only extend the lifespan of pressure valves but also reduce maintenance costs, ultimately leading to enhanced system reliability for users across various sectors.

Exploring the Unique Features and Applications of the Best Pressure Valves for Global Buyers

| Material | Application | Pressure Rating (psi) | Temperature Range (°F) | Longevity (Years) |

|---|---|---|---|---|

| Stainless Steel | Water Supply | 150 | -40 to 250 | 15 |

| Brass | Gas Lines | 200 | -20 to 180 | 10 |

| PVC | Chemical Processing | 100 | -20 to 140 | 5 |

| Ductile Iron | Oil Transportation | 300 | -40 to 350 | 20 |

| Aluminum | Air Conditioning | 75 | -10 to 120 | 12 |

Best Practices for Pressure Valve Maintenance: Ensuring Safety and Efficiency in Operations

Maintaining pressure valves is crucial for ensuring operational safety and efficiency across various industries. Regular maintenance practices can prevent malfunctions that may lead to hazardous situations. A good starting point is to establish a routine inspection schedule. During these inspections, look for signs of wear and tear, such as corrosion or leaks, and ensure that all moving parts are adequately lubricated. Additionally, it's important to verify that the pressure settings are calibrated correctly to match operational requirements, thereby minimizing risks associated with overpressure scenarios.

Another best practice is to implement a comprehensive documentation system for maintenance activities. Keeping detailed records of inspections, repairs, and replacements can help in identifying patterns or recurring issues, which can inform future maintenance strategies. This proactive approach not only enhances the longevity of the valves but also fosters greater accountability within the operations team.

Training employees on proper operating procedures and the importance of timely maintenance checks further underlines the commitment to safety and efficiency, ensuring that pressure valves perform optimally in their designated applications.

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy