-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

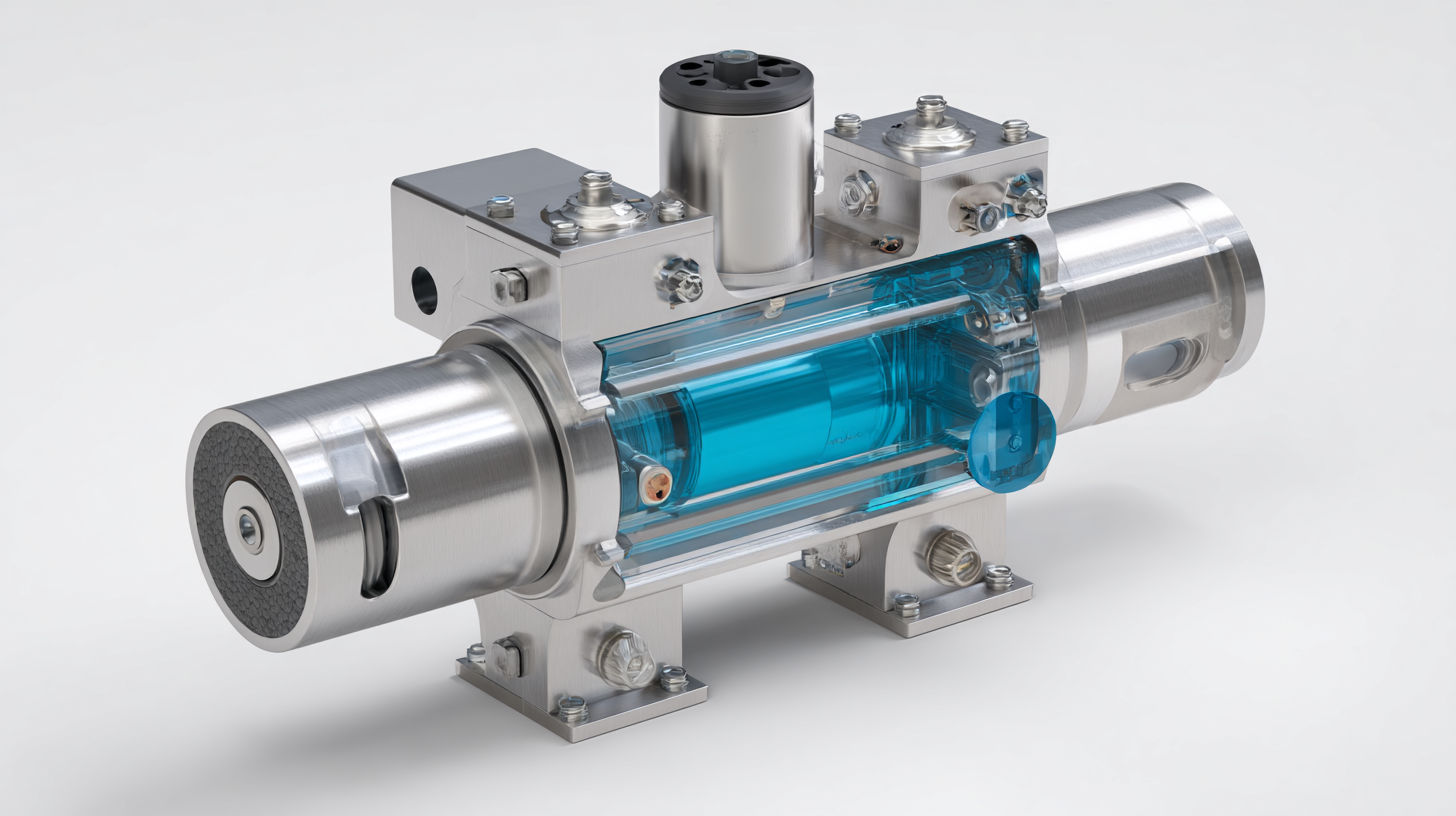

Innovative Solutions for Optimal Performance with Best Flow Control Valves

In today’s competitive industrial landscape, optimizing performance while ensuring efficiency has become paramount for organizations across various sectors. Recent studies indicate that the global flow control valve market is projected to reach USD 11.09 billion by 2027, driven by the increasing need for automated systems and advanced process control solutions. Flow control valves are critical components in regulating the flow and pressure of fluids, enhancing not only system efficiency but also energy conservation. Industry reports emphasize that the right flow control valve can significantly minimize operational costs and downtime, making it essential for businesses to adopt innovative strategies for selecting and implementing these vital devices. As industries continue to evolve, the integration of cutting-edge technologies and best practices in flow control valve utilization will play a crucial role in achieving optimal operational performance.

Innovative Technologies in Flow Control Valves for Enhanced System Efficiency

In the realm of industrial automation, flow control valves play a crucial role in optimizing system performance and efficiency. Recent advancements in technology have led to the development of innovative flow control valve designs incorporating smart features such as real-time monitoring and automated adjustments.

According to a report by MarketsandMarkets, the global flow control valve market is projected to reach $16.5 billion by 2025, driven by increasing demand for automation across various sectors, including oil and gas, water and wastewater management, and manufacturing.

One standout technology in this space is the introduction of smart flow control valves equipped with Internet of Things (IoT) capabilities. These valves enable remote monitoring and control, allowing for immediate responses to changes in operational conditions.

A study from Frost & Sullivan indicates that smart valves can reduce energy consumption by up to 30% by optimizing flow rates and minimizing leaks. Such capabilities not only enhance system efficiency but also contribute significantly to sustainability efforts within industries, aligning with global trends toward greener practices.

It's clear that innovative technologies in flow control valves are essential for achieving optimal performance and maximizing operational savings.

Key Performance Metrics for Selecting Best Flow Control Valve Types

When selecting the best flow control valves for optimal performance, there are several key performance metrics that should be considered. According to a report by Grand View Research, the global market for flow control valves is projected to reach $25 billion by 2027, highlighting the increasing demand for efficient fluid management systems across various industries. These metrics include flow rate, pressure drop, and response time, which directly impact the efficiency of systems in sectors such as oil and gas, water treatment, and manufacturing.

Flow rate is perhaps the most critical metric, as it determines how much fluid can pass through the valve under specific operating conditions. For instance, a well-designed valve can optimize flow rates by up to 30%, significantly reducing operational costs. Additionally, pressure drop is essential for maintaining system integrity; excessive pressure loss can lead to increased energy consumption and equipment fatigue. A recent study by the American Society of Mechanical Engineers (ASME) emphasizes that a well-optimized flow control valve contributes to energy savings of up to 20% across typical industrial applications. Thus, carefully evaluating various valve types based on these performance metrics can lead to better decision-making and enhanced system functionality.

Performance Metrics of Flow Control Valves

The following bar chart illustrates the performance metrics of various types of flow control valves. The metrics include Flow Rate (GPM), Pressure Drop (PSI), and Control Precision (%). These metrics are crucial for selecting the appropriate flow control valve to achieve optimal performance.

Impact of Flow Control Valves on Energy Savings and Operational Costs

Flow control valves play a pivotal role in enhancing energy efficiency and reducing operational costs across various industries. By precisely regulating the flow of fluids, these valves ensure that systems operate within optimal parameters, minimizing losses associated with over-pumping and energy waste. Through the implementation of advanced valve technologies, companies can achieve significant energy savings, translating to lower utility bills and improved overall sustainability.

The direct impact of flow control valves on operational costs cannot be overstated. Efficient flow management reduces wear and tear on pumps and other equipment, extending their lifespan and decreasing maintenance expenses. Additionally, automating flow control can lead to more predictable expenses, helping businesses better manage budgets and forecast future costs. As industries increasingly prioritize sustainability, the adoption of innovative flow control solutions also positions companies as leaders in energy efficiency, aligning their operations with global environmental goals.

Innovative Solutions for Optimal Performance with Best Flow Control Valves

| Flow Control Valve Type | Energy Savings (%) | Operational Cost Savings (%) | Industry Application | Recommended Usage Hours (per week) |

|---|---|---|---|---|

| Hydraulic Control Valve | 15% | 10% | Manufacturing | 40 |

| Pneumatic Control Valve | 12% | 8% | Oil & Gas | 50 |

| Electric Control Valve | 20% | 12% | HVAC Systems | 60 |

| Ball Valve | 10% | 5% | Water Treatment | 30 |

| Globe Valve | 18% | 7% | Chemical Processing | 45 |

Industry Trends: Advances in Flow Control Valve Applications Across Sectors

The flow control valve industry is witnessing significant advancements across various sectors, driven by the increasing demand for efficient fluid and gas management systems. According to a recent Markets and Markets report, the global flow control valve market is projected to reach USD 19.98 billion by 2025, growing at a CAGR of 6.9% from 2020 to 2025. This growth is largely attributed to the rising need for optimized operational efficiency in industries such as oil and gas, water and wastewater treatment, and chemical processing.

The flow control valve industry is witnessing significant advancements across various sectors, driven by the increasing demand for efficient fluid and gas management systems. According to a recent Markets and Markets report, the global flow control valve market is projected to reach USD 19.98 billion by 2025, growing at a CAGR of 6.9% from 2020 to 2025. This growth is largely attributed to the rising need for optimized operational efficiency in industries such as oil and gas, water and wastewater treatment, and chemical processing.

Recent innovations in flow control technology have led to the development of smart valves equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance. A report by Research and Markets reveals that the adoption of smart flow control solutions is expected to increase by 20% annually, reflecting a shift towards more automated and data-driven operations. These advancements not only enhance performance but also contribute to sustainability, as they improve resource management and reduce energy consumption across various applications. As industries continue to adapt to these trends, the role of advanced flow control valves will become increasingly crucial in achieving optimal performance and efficiency.

Case Studies: Real-World Implementations of High-Performance Flow Control Solutions

In recent years, industries have increasingly recognized the importance of efficient fluid control in enhancing operational performance. A comprehensive study by the International Journal of Fluid Mechanics highlights that optimizing flow control methods can lead to energy savings of up to 30%. This significant reduction not only diminishes operational costs but also contributes to sustainability goals by lowering overall energy consumption. Case studies illustrate this shift; for instance, a petrochemical facility implemented advanced flow control valves that improved flow accuracy by 25%, resulting in a notable decrease in material waste.

Moreover, the success story of a major food processing plant showcases the real-world impact of innovative flow control solutions. By integrating smart valve technologies capable of real-time data analytics, the facility achieved a 40% increase in system responsiveness. According to the Flow Control Association, this increase in performance not only enhanced product quality but also improved compliance with strict industry regulations. As various sectors adopt these cutting-edge technologies, the potential for continuous improvement in flow management becomes increasingly evident, driving both economic and environmental benefits.

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy