-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

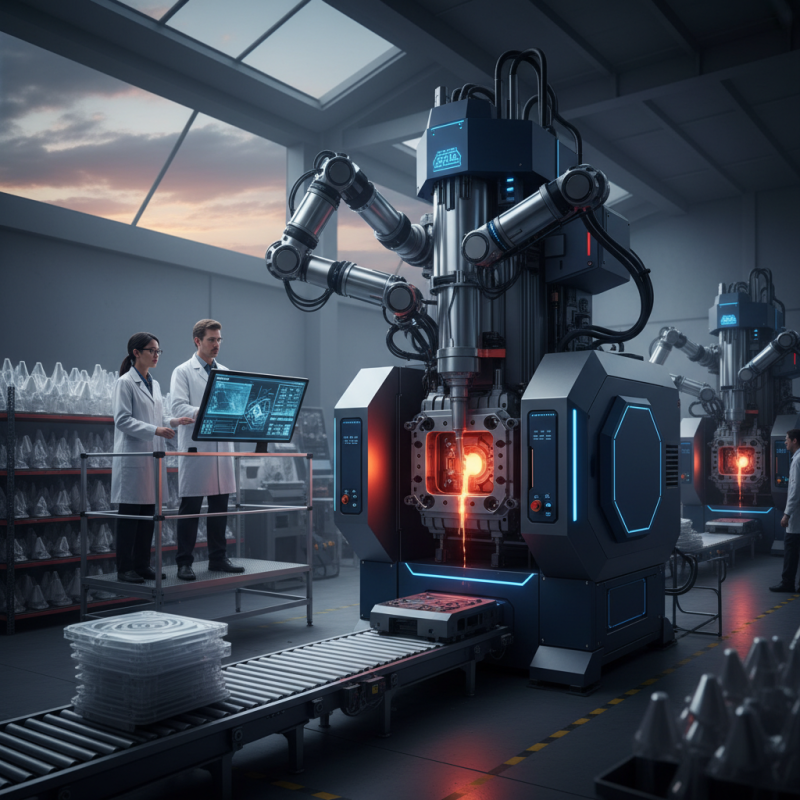

What is an Injection Machine Robot and How Does It Work?

The "Injection Machine Robot" is revolutionizing the manufacturing landscape. Experts, like Dr. Alice Chen, a leading authority in robotics, state, "These robots enhance precision and efficiency in production." This technology merges the art of injection molding with automation, creating a remarkable synergy.

An Injection Machine Robot automates the intricate process of molding plastics and other materials. It operates by injecting molten substances into molds to form desired shapes. This reduces human error and minimizes waste during production. The robots work tirelessly, producing thousands of parts in a fraction of the time.

However, not all is perfect with this technology. Implementation can be costly and requires skilled personnel to oversee operations. Additionally, reliance on automation can lead to job displacement. As industries adopt these robots, it’s essential to reflect on the balance between efficiency and employment.

Definition of Injection Machine Robots and Their Purpose

Injection machine robots play a crucial role in manufacturing. They automate the process of injection molding. This technique involves melting materials, typically plastics, and injecting them into molds. The purpose is to create precise and consistent products. These robots enhance production efficiency and reduce labor costs.

When selecting an injection machine robot, consider its load capacity and speed. These factors greatly influence production quality. Ensure the robot fits well within your workflow. A misaligned robot can lead to defects. Small errors can accumulate and cause significant issues later.

Tips: Regularly inspect your robot for wear and tear. Even high-quality machines need maintenance. Moreover, ensure staff are trained properly. Misunderstandings can lead to accidents. Create a culture of safety and awareness. Quality controls should be part of your daily routine. This helps catch mistakes early. Proper planning minimizes complications. Always evaluate your processes critically.

Components of an Injection Machine Robot and Their Functions

Injection machine robots are complex systems used in manufacturing processes. They involve several key components, each with its own function. Understanding these parts can help optimize production efficiency.

The injection unit is crucial. It melts plastic pellets, transforming them into liquid for molding. The drive system controls the injection process. Hydraulic or electric motors provide the force needed. The clamping unit holds the mold in place. Accurate pressure is necessary here. This part ensures the final product has no defects.

Sensors play a vital role too. They monitor temperature and pressure. If something is off, production may halt. Errors can arise from improper settings or worn-out components. Regular maintenance is essential. Minor oversights can lead to significant setbacks in production. Overall, a machine's efficiency relies on all these components working together smoothly.

Components of an Injection Machine Robot and Their Functions

Working Principles of Injection Machine Robots Explained

Injection machine robots are essential in modern manufacturing. They operate on a simple but effective principle: precision and speed. The injection molding process involves heating plastic pellets until they melt. Once melted, the material is injected into a mold under pressure. This is where the robot plays a crucial role.

These robots automate the handling of molds and facilitate the injection process. They pick up and position molds accurately. Their movements are swift and coordinated. This helps in reducing cycle time, which is key in production efficiency. However, the programming of these robots can sometimes lead to issues. Misalignment or incorrect settings may result in defects. It’s vital to regularly maintain and calibrate the machines to ensure they function correctly.

A fine balance is necessary when operating injection machine robots. Too much speed might lead to errors, while too little can slow production. Operators must be trained to recognize signs of malfunction. Even small mistakes can lead to waste and increased costs. This highlights the importance of human oversight in an automated process, making it a partnership between human skill and machine efficiency.

Applications of Injection Machine Robots in Various Industries

Injection machine robots play a vital role in various industries, streamlining production processes. In the automotive sector, data shows that over 70% of vehicle manufacturers now use these robots for plastic part production. They ensure consistency and reduce cycle times. This automation can cut labor costs significantly. However, integration gaps still exist in some legacy systems, posing challenges.

In the consumer goods industry, injection robots have improved production efficiency by 40%. Brands leverage these robots to produce complex shapes and meet demand. The electronics sector, too, benefits. Robots handle the delicate assembly of parts with precision. The downside is the initial investment; it can be substantial. Many companies hesitate to adopt this technology fully.

Healthcare is another field where injection machine robots shine. They facilitate the mass production of syringes and other medical devices. Here, safety and quality are critical. Yet, automated processes can lead to quality control issues. Continuous monitoring is essential to maintain standards. Despite these challenges, the advantages of injection machine robots are clear.

Future Trends and Innovations in Injection Machine Robot Technology

The injection machine robot industry is evolving rapidly. Future trends indicate a significant rise in automation and efficiency. According to a recent report, the global market for injection molding machine robots is projected to exceed $5 billion by 2025. This growth is fueled by the demand for precision in manufacturing processes. Companies are seeking ways to reduce waste and enhance productivity.

One promising innovation is the use of artificial intelligence. AI can optimize the performance of injection molding robots. It helps in predictive maintenance and improves overall operational efficiency. Additionally, advancements in materials science are paving the way for more versatile and durable robot components. However, challenges remain. Not all manufacturers can adapt quickly to these new technologies. Resistance to change can slow down progress in the industry.

Another area of interest is sustainability. The use of eco-friendly materials in injection molding is increasing. Robots can be programmed to use these materials effectively, reducing environmental impact. Yet, the transition to greener practices often requires significant investment and research. Many businesses are hesitant to take the leap. The future of injection machine robots lies in balancing innovation with practical implementation.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy