-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

The Future of Smart Automation in Best Automatic Valves

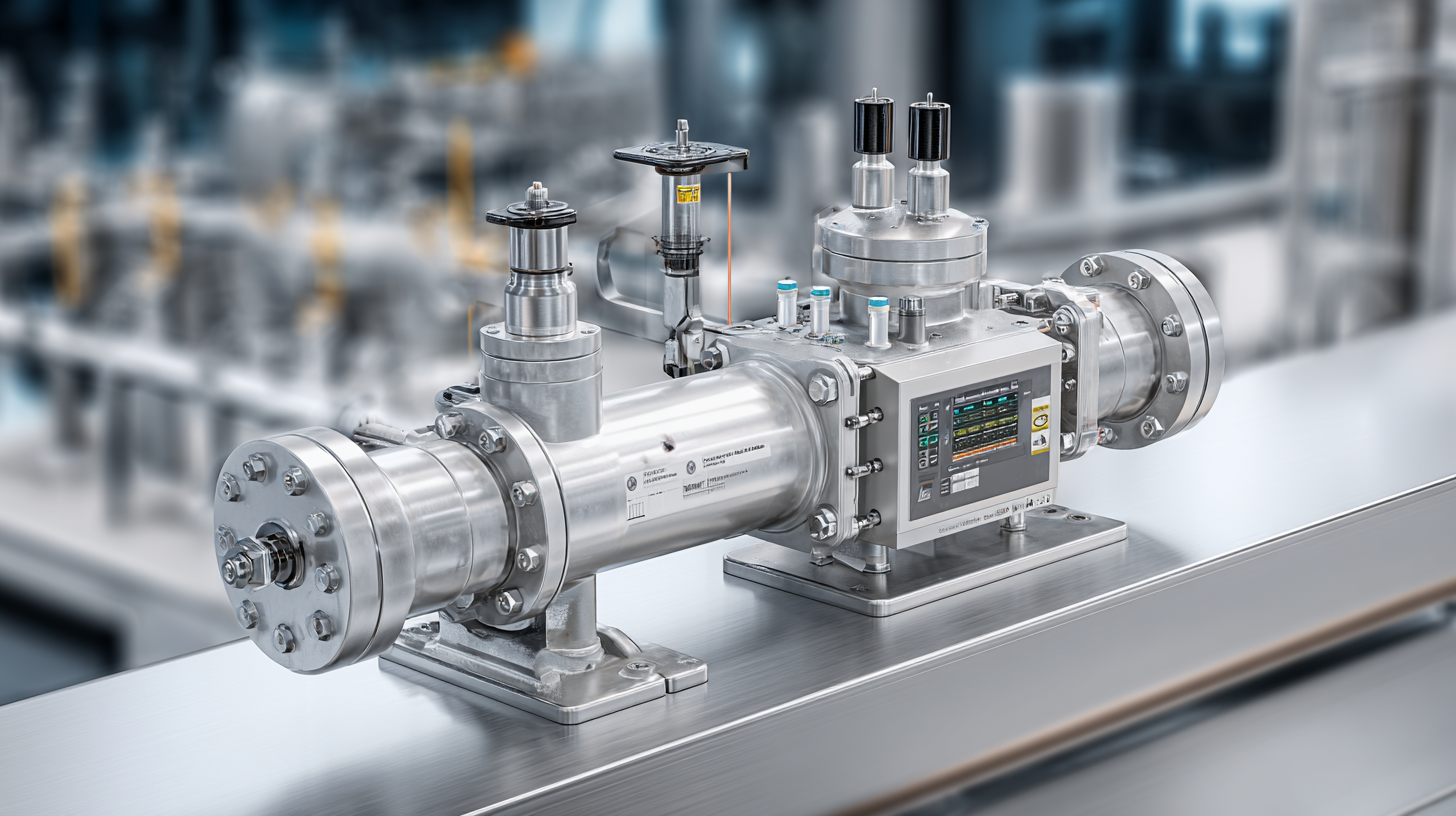

As industries continue to evolve towards greater efficiency and precision, the role of smart automation in the realm of Automatic Valves becomes increasingly pivotal. This blog delves into the future of smart automation technology, highlighting the cutting-edge innovations that are set to redefine how Automatic Valves operate within various sectors. From enhancing operational reliability to improving response times, smart automation integrates advanced sensors and digital monitoring systems to streamline valve performance. Additionally, we will explore the detailed technical specifications and numerical data that accompany the top types of Automatic Valves on the market today. By understanding these advancements and their implications, businesses can make informed decisions that not only boost productivity but also foster sustainable practices in fluid control systems. Join us as we navigate the exciting landscape where automation meets valve technology, setting the stage for a smarter industrial future.

The Impact of Industry Certification on Automatic Valve Production Standards

The industry of automatic valves is experiencing a significant transformation, heavily influenced by the implementation of rigorous certification standards. According to a report by the International Society of Automation (ISA), nearly 70% of manufacturers agree that industry certifications enhance product quality and ensure compliance with safety regulations. Certifications like ISO 9001 and the American National Standards Institute (ANSI) not only standardize production processes but also mitigate risks associated with valve failure, which can lead to costly downtime and safety hazards.

Moreover, ongoing advancements in smart automation technology are driving the need for certified automatic valves that can efficiently handle complex tasks. A study published by Transparency Market Research highlights that the global market for smart valves is expected to reach $5.2 billion by 2024, with industry certification playing a pivotal role in this growth. Enhanced production standards not only ensure product reliability but also foster consumer trust, paving the way for a more robust and innovative automatic valve sector. As automation continues to evolve, companies committed to meeting stringent certification requirements will undoubtedly gain a competitive edge in the market.

Digital Transformation in the Automatic Valve Sector: Trends and Innovations

The automatic valve sector is undergoing significant digital transformation, driven by advancements in smart automation technologies. According to a report by MarketsandMarkets, the global smart valve market is projected to reach $7.87 billion by 2025, growing at a CAGR of 4.9%. This growth is largely fueled by the increasing demand for automation in various industries, including oil and gas, water and wastewater management, and power generation. As companies strive to enhance operational efficiency and reduce costs, smart valves equipped with IoT connectivity and data analytics are becoming essential tools for real-time monitoring and control.

The automatic valve sector is undergoing significant digital transformation, driven by advancements in smart automation technologies. According to a report by MarketsandMarkets, the global smart valve market is projected to reach $7.87 billion by 2025, growing at a CAGR of 4.9%. This growth is largely fueled by the increasing demand for automation in various industries, including oil and gas, water and wastewater management, and power generation. As companies strive to enhance operational efficiency and reduce costs, smart valves equipped with IoT connectivity and data analytics are becoming essential tools for real-time monitoring and control.

Innovations in the automatic valve sector are also being propelled by the adoption of Industry 4.0 principles. A study from Deloitte highlights that 61% of manufacturers consider data analytics a key driver for decision-making processes. Integrating machine learning algorithms into valve management systems allows for predictive maintenance, which reduces downtime and increases reliability. Furthermore, advancements in materials and smart materials contribute to valve performance, extending their lifespan and minimizing leakages. As industries embrace these digital transformations, the automatic valve market is set to evolve, ensuring a smarter, more efficient future.

Top Technologies Revolutionizing Smart Automation in Valve Systems

The evolution of smart automation in automatic valves is significantly reshaping the industries that rely on fluid control and management systems. According to a recent report by Market Research Future, the global smart valve market is projected to reach USD 6 billion by 2025, growing at a CAGR of 12%. This surge is driven by innovative technologies such as the Internet of Things (IoT), advanced sensor systems, and machine learning algorithms that enhance operational efficiency and predictive maintenance capabilities.

One of the key technologies revolutionizing smart automation in valve systems is the integration of predictive analytics. By utilizing real-time data from sensors and IoT devices, companies can forecast potential failures and optimize maintenance schedules, which can reduce downtime by up to 30%. Additionally, the deployment of cloud computing solutions facilitates remote monitoring and control, empowering operators to make informed decisions swiftly and reduce operational costs.

Tips for implementing smart automation in your valve systems include investing in compatible sensors that can effectively communicate with existing infrastructure, leveraging cloud technology for centralized data management, and training staff to utilize advanced analytics tools. As the industry continues to grow, focusing on these elements will ensure a seamless transition to a more automated and efficient future.

The Future of Smart Automation in Best Automatic Valves - Top Technologies Revolutionizing Smart Automation in Valve Systems

| Technology | Key Features | Benefits | Applications |

|---|---|---|---|

| IoT Integration | Remote monitoring, data collection | Increased efficiency, real-time analytics | Water management, industrial processes |

| Artificial Intelligence | Predictive maintenance, optimization | Reduced downtime, cost savings | Manufacturing, oil and gas |

| Smart Sensors | Real-time pressure, flow measurement | Improved safety, enhanced control | HVAC, chemical processing |

| Cloud Computing | Data storage, remote access | Scalability, data backup | Energy sector, civil engineering |

| Blockchain Technology | Secure transactions, data integrity | Enhanced security, transparency | Supply chain, water distribution |

Market Analysis: Demand for Smart Automated Valves in Global Trade

The demand for smart automated valves has seen significant growth in recent years, a trend that is projected to continue in the coming years. The global pneumatic market, valued at USD 18.829 billion in 2022, is anticipated to reach USD 34.583 billion by 2028, reflecting a robust CAGR. This surge is largely driven by the increasing implementation of automation technologies across various industries, which enhances operational efficiency and reliability.

Moreover, the marine valves and actuators market is also expected to grow, with projections estimating it to reach USD 5.8 billion by 2032, growing at a moderate CAGR of 4.5%. Such growth highlights the evolving landscape where industries are prioritizing advanced control systems and IoT integrations in their valve solutions. Additionally, the HVAC valve sector is expanding as demand rises for intelligent valves equipped with sensors and smart technology, further reinforcing the critical role of automation in today's global trade landscape.

Future Prospects: Integrating IoT and AI in Automatic Valve Designs

As we look towards the future of smart automation in automatic valves, the integration of IoT (Internet of Things) and AI (Artificial Intelligence) is set to redefine the industry. According to a report by Market Research Future, the smart valves market is projected to reach $11.90 billion by 2025, driven by advancements in connectivity and automation technologies. By incorporating IoT, automatic valves can provide real-time data analytics, enhance monitoring capabilities, and improve decision-making processes. This interconnectedness enables systems to detect anomalies and optimize performance through predictive maintenance.

Incorporating AI into automatic valve designs allows for advanced algorithms to analyze complex data sets, leading to improved efficiency and reliability. For example, an AI-driven system can learn from historical performance data and adapt in real time to varying operational conditions, thus minimizing downtime and maximizing efficiency. Industry experts emphasize that these technologies not only streamline operations but can also contribute significantly to energy savings, with studies showing potential reductions of up to 30% in energy usage for automated systems.

Tips: To stay ahead in this rapidly evolving field, companies should invest in training their workforce on IoT and AI technologies. Additionally, consider collaborating with technology partners who have expertise in these areas, ensuring smooth integration into existing systems. Embracing these innovations is not just about keeping pace; it’s about leading the way in smart automation.

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy